Embodied Carbon Assessments With Vectorworks Embodied Carbon Calculator

Early design stage carbon assessments provide designers with insight into their project’s carbon footprint using generic materials to show design intent. As the design progresses, manufacturer-specific data from Environmental Product Declarations (EPDs) is needed to accurately reflect the impact of installed products.

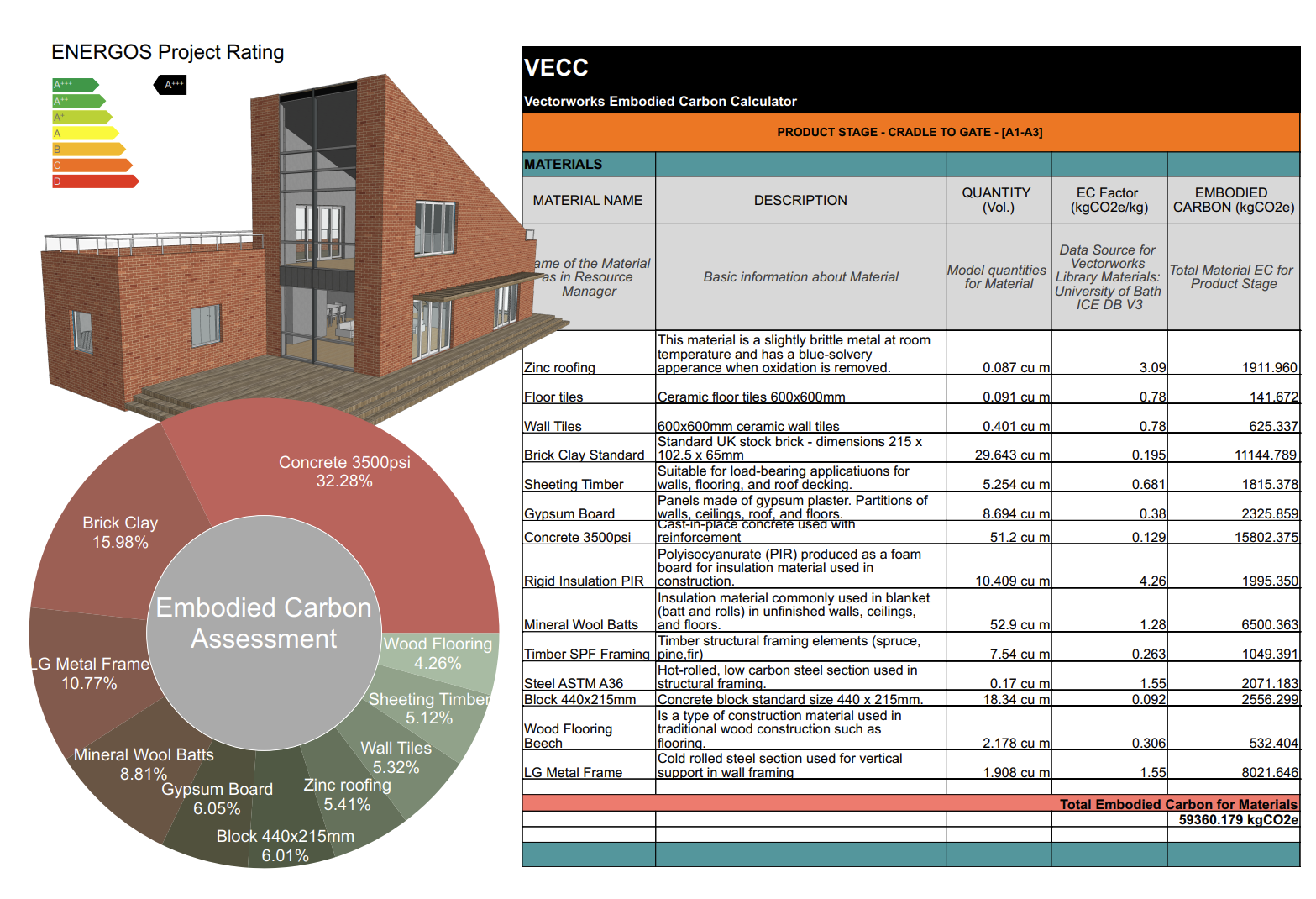

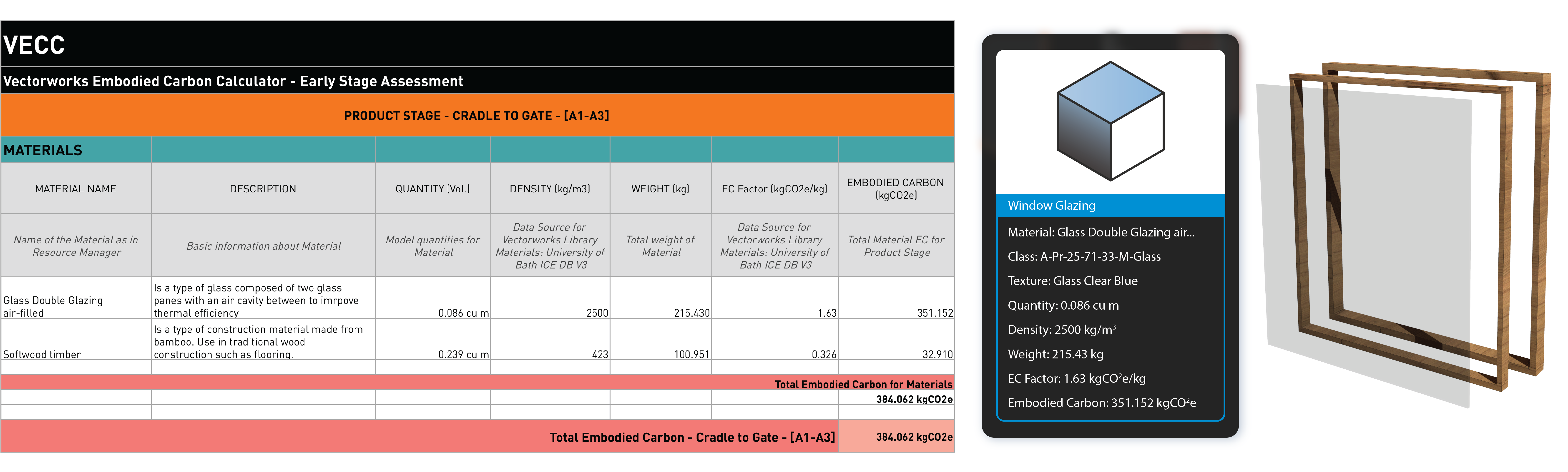

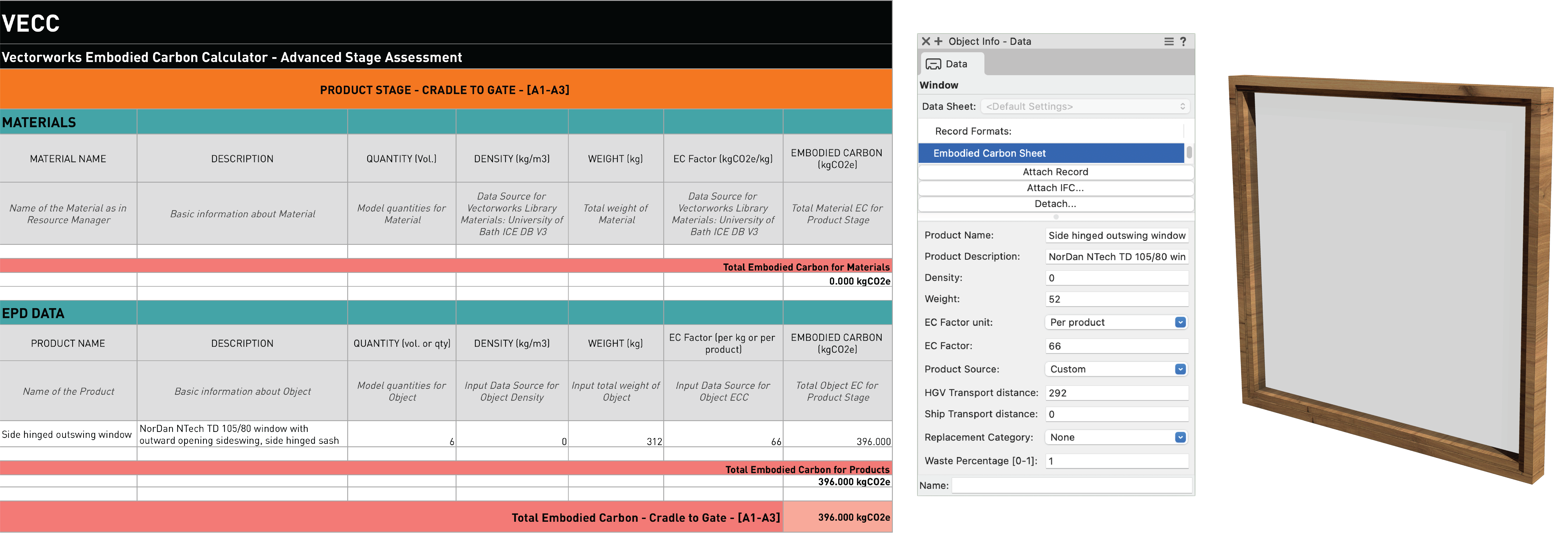

Vectorworks 2024 introduces a two-staged approach for its embodied carbon calculator (VECC) that allows for flexibility and accuracy in calculating whole-life cycle carbon. This includes an early-stage assessment for quick carbon footprint estimates and an advanced-stage assessment that incorporates specific product data.

What Is Embodied Carbon?

In the building industry, embodied carbon refers to the greenhouse gas emissions from manufacturing, transportation, installation, maintenance, and disposal of building materials.

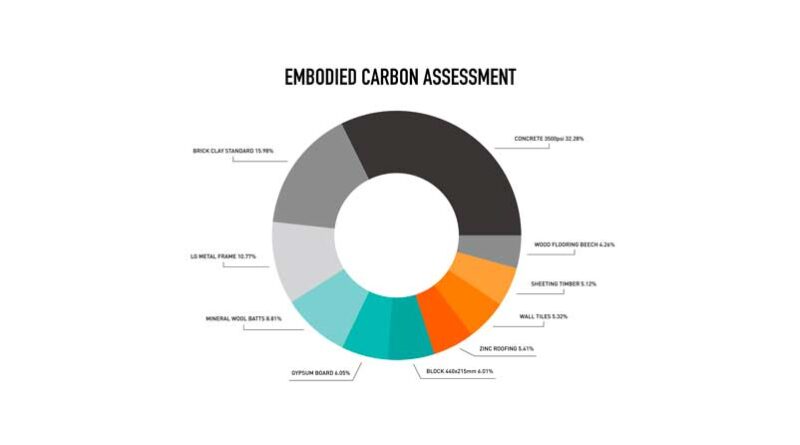

Operational carbon, on the other hand, refers to the emissions from building energy consumption. These calculations are handled by Vectorworks’ Energos feature. Together with the VECC, you can confidently track whole-lifecycle carbon.

Embodied carbon is also called upfront carbon because its emissions are released by the time the building is completed and before it’s in use. Crucially, it cannot be improved after construction, unlike operational carbon, which can be upgraded by installing more efficient HVAC systems, or better insulating windows, for example.

Architects have been aware of the need to reduce operational energy demands for a long time, so embodied carbon has come into focus as its share in whole-lifecycle carbon is becoming larger through a combination of operational efficiency gains and grid decarbonization, among other things.

What’s increasingly clear is the importance to look at things holistically and asses a project’s whole-lifecycle carbon to reduce carbon footprints and drive down CO2 emissions.

Generic Materials Vs. Manufacturer-Specific EPD Data

During the early design stages, it’s good practice to describe project materialization in basic ways. This allows you to quickly produce design concepts that you can specify later in the design process. Generic materials convey the design intent and serve as a visual representation of the project.

Vectorworks’ default material resources library contains hundreds of generic materials, with almost 400 of them already populated with data necessary for embodied carbon calculations, such as embodied carbon factor and density.

The values for these generic materials are typically sourced from available databases, with Vectorworks utilizing the ICE Database, an industry-standard source of embodied carbon data. This database provides interpolated values based on statistical market data for various building materials and products in the construction industry.

In the later design stages, you’ll choose specific materials and products. This allows for more accurate carbon assessments using exact data coming from manufacturers of specified materials and products. There are many EPD libraries available to source this information from and populate your BIM model, replacing generic carbon data.

Vectorworks Embodied Carbon Calculator – Supporting Whole Lifecycle Carbon Assessments

The VECC is specifically built to support the workflow described in this article. Using the worksheet and its functionality, you can reliably generate both early-project carbon estimations and later-phase carbon data based on accurate database values.

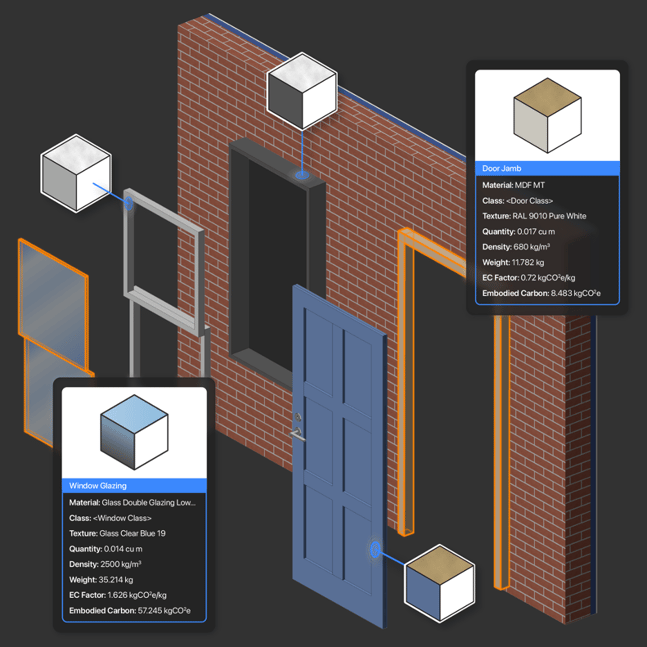

Vectorworks 2024 introduces Materials to Door and Window subparts, so you can assign a generic double glazing and softwood timber materials to your windows in the early design stages to help visualize your design and run an early stage carbon assessment that will calculate accurate quantities of double glazing and softwood timber from your model.

Once you specify windows as a product from a selected manufacturer, you can assign data they provide for the entire window unit using a custom Record Format in Vectorworks found in the Resource Manager. When you run the advanced stage carbon assessment version of VECC, it will automatically take those specific values into account and remove generic double glazing and softwood timber, so these windows are not double counted.

Looking to take advantage of what the VECC has to offer? You can find more information here,

For an in-depth exploration on Vectorworks University. Here you’ll find a downloadable sample file containing instructions on how to use this powerful tool.

This article was originally published by Vectorworks and written by Alex Altieri.

Follow Irish building magazine on LinkedIn for the latest news and updates