Sustainable Design With A Smart BIM Model

Integrating Building Information Modelling (BIM) into daily architecture workflows provides an enormous opportunity to streamline and amplify collaborative work. The focus lies on process optimisation as well as efficient collaboration with all project participants.

“The challenge is to implement a comprehensive system that is also easy to use,” said Matteo Neustadt, an architect at LH Architekten. The Hamburg-based architecture firm provides an excellent example of a successful BIM application. At a time when sustainability is becoming increasingly important, the firm demonstrates how state-of-the-art technologies like BIM can make a valuable contribution to shaping a more environmentally friendly future.

Calculating carbon emissions with Vectorworks

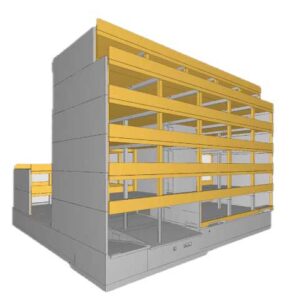

With the “Timber-Office” project, LH Architekten has shown how sustainability and BIM can go hand in hand. The office building, constructed using an innovative wood-concrete hybrid construction method, won first place in the Sustainability category at the 21st buildingSMART User Day.

Using Vectorworks, the architects compared various building shell construction options. The components in the model were linked to the values from ÖKOBAUDAT, a German standardised database for life-cycle assessments of buildings, allowing the architects to approximate CO2 emissions in advance. This approach allowed the architects to estimate how different construction materials affect the ecological footprint of a building in the early stages of the project when changes are less costly. This allows for more precise planning and conscious decision making in favour of more environmentally friendly alternatives.

Building components and their limits | Working with the Vectorworks Data Manager

“The Data Manager is a powerful tool that allows fundamental control over the data flow within the 3D model,” Neustadt said. For instance, adjusting the materials specified for different wall components is straightforward and the changes can be seen in both the BIM model geometry and in the carbon data attached to that geometry. The same applies to floors, ceilings, and roofs.

At LH Architekten, the information on components is read from a custom-developed coding system, cross-referenced with internal worksheets, and automatically transferred to the desired IFC data in the background while working in Vectorworks. This enables not only the collection of individual values but also the identification of relationships between different properties. For instance, the program can automatically identify which cost group a construction element belongs to.

“Our method has the advantage that we can centrally manage information within the Vectorworks document. The Data Manager can assign this data to objects in the background while working,” said Udo Schaumburg, partner at LH Architekten.

Sustainability throughout the entire construction process

Vectorworks’ data visualisation capabilities offer additional potential for quality assurance within the model, providing a quick graphical overview of the building. This allows quality checks to begin during the modelling process. Classification and consistent naming in Vectorworks also enable quick and efficient model validation by allowing easy sorting and filtering of objects when asking questions such as: What is the distance between a component and the ceiling or floor? How much space is there between a pipeline and the floor, and can people move there?

Thanks to comprehensive data collection, potential issues can be identified and resolved early, avoiding rework and the waste of resources and energy. This significantly contributes to sustainability throughout the entire construction process.

Follow Irish building magazine on LinkedIn for the latest news and updates.