PM Group – A Digital Journey

Paul Hannan, Group DeLPD Applications Manager at PM Group discusses his perspective on technology and how it has improved Lean processes within the organisation.

Designing and managing complex projects for high profile clients across Europe, the USA and Asia, requires PM Group to be operating at the top of its game as an organisation. It requires consistency in best practices and approach; best in class technology and workflows; flexibility to scale, as needed by the projects; and deep insights garnered from data.

With over 3,500 people and a turnover of €400m PM Group is a recognised leader in the pharma, medtech, mission critical, food and advanced manufacturing sectors. The company has a 49-year track-record in project management, process design, facility design and construction management for leading multinational companies. Clients include, MSD, Bayer, Boehringer Ingelheim, Johnson Matthey, Boston Scientific, PepsiCo, Diageo, and Pernod Ricard.

Building long-standing relationships with major multi-national clients is the result of quality project delivery. Digital technologies, sustainability (net zero, carbon targets), innovation and Industry 4.0 initiatives are helping to shape the business and set the foundation for future growth.

Paul Hannan is the Group DeLPD (Digitally enabled Lean Project Delivery) Applications Manager. He is a member of the PM Group Digital Leadership Team and is also Digital Lead for Engineering.

Strategy for digital design

A number of years ago, PM Group began to work in earnest on a new business strategy to take the Group up to 2025. “An output of that was our digital strategy, which was developed over time. To develop that, we took soundings internally, from our customers and from industry, to develop, initially what our digital vision was, and then from that, to our digital strategy. At a very high level our digital vision guides our transformation to a digital organisation; it is where we want to get to. In short, we want to build a highly connected workforce with fast reliable access to data, to deliver innovative, Lean and sustainable solutions to meet the changing future needs of our clients through the lifecycle of their operation. Essentially, it’s about preparing ourselves for the future to ensure we as an organisation, and as a business, are in the best possible position to continue to meet our clients’ requirements and growth.”

Substantial investment is going back into the company to deliver on the new strategy. He continues to describe how the vision is distilled down through different areas, with various internal projects to be delivered within the timeframe of the strategy to align with both the vision and the three main streams of the strategy.

First and foremost, among those three is the digital journey: “to accelerate digitalisation within PM Group, to develop and recruit new skill sets to support growth strategy, to integrate our core business systems and to automate routine workflows.”

Even before the new strategy, new roles were being created within the organisation, and this has continued, with jobs including digital technologists, project information engineers and data analysts now an integral part of how the company operates.

“My own role is a new role—digitally enabled Lean project delivery. The core part of my role is to manage our applications that we use in our project delivery, from licensing to compliance. We have a number of technology partners, Autodesk being one of them, and essentially my main responsibility is to manage our relationship.”

Changing up traditional structures has allowed the company to redirect focus to enable new ways of working. “There have been new departments created and also amalgamations—elements that may have sat in one department have been pulled out, because we’ve seen that, from a strategy perspective, we really need to focus in on a particular area.

DeLTa programme

The Digitally-enabled Lean Transformation (DeLTa) programme is a key driver for the business strategy. “It will dramatically improve our efficiency and performance across every aspect of our business,” Hannan says. “It adapts Lean principles and practices to the work that we do in order to remove wasteful activities and friction, which will make everyone’s working life more rewarding and less stressful. We commenced with a comprehensive training and mentoring programme for all of our 3,500 people to provide them with a shared understanding for applying Lean and digitalisation to our business. We don’t see it as just as a digital transformation, it has brought Lean and digital together.”

With new roles and recruits specific to the endeavour, Hannan underlines that “PM Group are not taking this effort lightly.” He adds, “It’s great that the company is investing in itself, to put us in the best possible position going forward. It’s where we see ourselves having some competitive advantage, not only to deliver on our customers’ requirements, but also for our own internal workflows and removing waste from the way we do things. It’s a really exciting time.”

All the efforts—numerous workshops, Voice of the Customer and other market research—are showing dividends now. “We have a structure going forward, we can see what our roadmap is, we can see where we need to get to. The DeLTa programme wraps around our strategy: it combines communications and training to more effectively inform our people.”

Integrated Project Delivery

“Our DeLTa programme really involves Lean and digitalisation together, and that’s why we don’t see this as just our digital transformation. A Lean mindset and approach enabled by digital is a powerful combination for transformation.”

There are four different areas of focus within that: flow, people, quality and digital.

“We’re looking for frictionless flow across the business and project delivery processes; we have a people focus in terms of dynamic collaboration and tiered agility; the third one is quality which encompasses zero waste and getting things done right first time; then the fourth one is digital which involves ‘getting there easier’, connecting our systems in real time and using our digital technology to get to where we want to go to more easily and safely.”

Tiered Agility

PM Group used a collaboration framework call ‘tiered agility’, which, Hannan explains, “ensures we work together, and it also enables each one of us to contribute our best each day.” He continues, “‘Agility’ speaks to the ability for us to respond and be nimble, fast, and accurate in our decision making, whether it is communications or escalations required to solve issues. ‘Tiered’ means having a structure that builds on what’s gone before and prepares for what’s coming next. Planning, doing, checking, and then acting or adapting is the framework. Ultimately, at the core of tiered agility is achieving high performance – both individually and in our teams.”

The different tiers align with activity: doing, coordination, managing and leadership, and on a practical level, communication occurs in team get-togethers or huddles. “We’re applying that to each of our objectives and leveraging our Lean tools. It’s a very visual and informative system. It has been in the organisation for four or five years now on certain projects. Once people hear about it and experience it, they want more of it, because it does work. It gives people back time.”

Challenges of change

Like any programme for change, Hannan admits, it throws up challenges, but advises that with good planning, a framework and communication of the vision, it is easier to bring people along on the journey with you. “I think it’s key for the change management team to identify and communicate the reasons why we’re doing this. Long-term we have a core vision, which is ultimately to make people’s lives easier. And I think once you can demonstrate that to people, it’s easier to bring them along on the journey.”

In such a big global business, working with different clients on big projects, not all change can happen at the same time. “At the moment, because we’re on that journey, some projects will be more digitally mature than others, but the intention is that we all get there safely together throughout this transformation, so that everybody’s singing from the same hymn sheet.”

Hannan is cognisant that this will always depend on what the customer wants. “We will still need to remain quite nimble because, even in terms of applications and technology, we might standardise on a certain application or certain technology or certain way of doing things, and our customer may want us to use a different way, so we’re trying to remain flexible.”

Design for sustainability

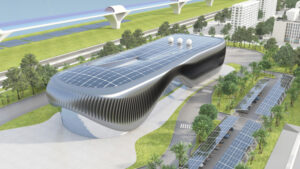

“We want to see ourselves, essentially, as a highly valued and creative delivery partner for our clients, building a more sustainable world with them. In our own business, we’ve measured our carbon footprint since 2009, and we’ve implemented environmental management systems across our office network. Last year, we committed to becoming carbon neutral and we’ve achieved that goal.”

To this end, PM Group has made numerous steps, including changing old pieces of equipment for more sustainable and energy efficient alternatives, using alternative fuels and renewables and factoring in carbon management to building designs, with full lifecycle assessments.

We’re looking forward in the future to being net zero, but I would say our greatest contribution to climate change mitigation will be through our sustainable building designs and our project delivery. We are continuing to develop this expertise and support, challenge and collaborate with our clients to help them achieve their carbon minimisation ambitions. None of this can happen without digital; it’s a key component.”

Cradle to cradle approach

Currently, much of the world’s resources are used in a linear manner, a cradle-to-grave approach, if you will. The cradle-to-cradle (C2C) approach, which is now becoming talked about in the industry, allows for a sustainable life cycle, reusing elements at the end of a building’s life.

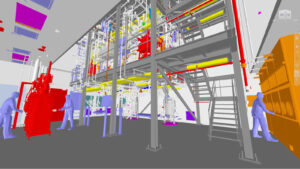

“The reuse mentality would be to take, for example, a piece of equipment and reuse it elsewhere, as opposed to going through the recycling process. To put the digital spin on that, it’s not possible without knowing the data about that piece of equipment, what the raw materials are, whether it’s operational, data associated with the operation, and so on. We need to have tags to identify a piece of equipment in our models so that when it does come to end of life, decisions can be made around reuse versus recycling.”

The capacity for reuse needs to be designed into products and processes from the beginning, thinking about how they can be separated and reused at the end of life.

He explains, “At the design stage, if you bury a piece of steel in a concrete element, it’s probably unusable afterwards because it’s encased in concrete. Whereas if you look at it from a design perspective, there may be other options to get the same output, that will make it reusable at some future stage.” Hannan jokes that this way of thinking has even infiltrated his own home improvements, where he plans to reuse old door lintels in another space.

The future of work

Even prior to COVID-19, PM Group would regularly involve employees in various different offices on projects together, so the technology to facilitate working in virtual teams was already in place. “It’s about being able to provide our clients with the capabilities they need anywhere in the world. ‘MOE’ is our multi-office execution model. We’re using our office network to deliver projects, using people in multiple locations, where traditionally everyone would need to be based in the same location—and our digital technologies are our key to making this happen.”

Innovation on the agenda

Hannan concludes noting that innovation is essential in creating competitive advantage. To foster this culture within the company, PM Group has developed its own internal structures, including the Innovation in Action Awards, which showcases internal innovations. “People get to submit their innovations and ideas and over the years some great new services have come out of that.”

“In our industry, innovation is constantly happening in processes and technologies,” Hannan notes, citing cell gene therapy and personalised medicines as two innovations which are throwing up new challenges which he believes automation and robotics will be crucial to solving. From using visualisation and AR technologies to give customers an immersive experience in advance of going to site, to using virtual reality to facilitate customer operator training, digital technology is changing the landscape. “Our challenge now really is to design for the unknown, with all the attendant requirements and need for regulatory and quality standards.”