International Standard “E-Thermal” Environmental Test Facility opens in GMIT

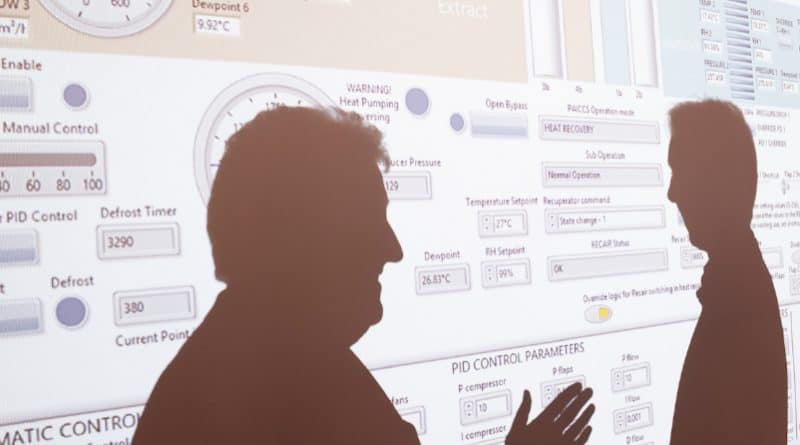

An international standard “E-Thermal” environmental test facility designed to assist Irish SMEs in developing new sustainable heating products was formally opened in GMIT by Deputy Seán Canney, Minister of State for Natural Resources, Community Affairs and Digital Development.

E-Thermal stands for Environmental Testing of a Heat-pump and Enthalpy Recovery Machine within an Advanced Laboratory. The facility has been established by GMIT’s integrated Sustainable Energy Technologies (iSET) research group with financial support of €360,000 from Galway-based company ProAir and Enterprise Ireland.

Speaking at the launch, Minister Canney says: “Climate Action is a priority for Government. Shortly we will publish an All of Government Action Plan to deal with Climate Change. Projects like the new “E-Thermal” Environmental Test Facility at GMIT is vital for industry to move towards our objectives. I commend GMIT, Enterprise Ireland and ProAir for their collaboration in establishing this facility in GMIT. I am delighted that ProAir and David McHugh are leading the way in a very effective way.”

Dr John Lohan, Principal Investigator and lecturer in the GMIT Dept of Mechanical and Industrial Engineering, says: “It is the first such test facility in Ireland capable of offering product development and pre-certification testing of sustainable heating and energy efficiency products to international test standards.”

“The laboratory can expose such products to a range of European weather conditions (temperature range -15oC to +35oC; relative humidity 10-90%) and monitor the performance of the new product when exposed to these conditions. Many different types of tests can be performed from short (one hour to 24 hour long), manual control tests, medium duration (one to 14 days) automated tests to long duration (one to 26-week) endurance, automated tests. This secure facility will facilitate Irish SMEs controlled and monitored access, 24/7.”

“The first product being tested is the very exciting “Aergoma” concept from Galway-based ProAir Heat Recovery Ventilation Systems. This integrated heat-pump and heat recovery ventilation system has the potential to substantially reduce both heating costs and carbon-dioxide emissions and ProAir expect to market this innovative product in mid-2020.” says Dr Lohan.

“The laboratory will also be used to support undergraduate and postgraduate projects for students of GMIT’s Energy Engineering and Mechanical Engineering programs. Research Assistant David Hunt, and PhD researcher on this project, is a former graduate of GMIT’s Energy Engineering Degree Programme and has played a central role in the design, construction and commissioning of this new facility. The current “E-THERMAL” project commenced in July 2018 and will run until June 2020.

The project team are all members of GMIT’s integrated Sustainable Energy Technologies (iSET) research group who conduct research on sustainable heating. The E-THERMAL project team consists of Dr Laurentiu Dimache and Dr John Lohan, Principle Investigators, Dr Naoise McSweeney, Research Fellow and David Hunt, Research Assistant.

David McHugh, Managing Director, ProAir, says: “Our company has had association with GMIT stretching back to the early noughties and the beginning of the energy faculty, so it was logical to contact John Lohan with an idea for a collaboration and a project like this. We are delighted with how this has progressed and look forward to the data which David and Naoise will produce. This type of facility is crucial to developing our ideas on low energy heating and ventilation systems.”

Gerard MacMichael, Head of the GMIT School of Engineering, says: “The collaboration between ProAir and iSET is an example of the nature of the applied research and innovation carried out by staff in the School of Engineering with industry. This particular relationship is very important as it informs and integrates with our energy engineering degree. Graduates of this honours course are in great demand.”

Visit the site for more details.